Selecting the Optimal PCBA Manufacturer for Your Undertaking

In today's interconnected world, the role of Printed Circuit Board Assembly (PCBA) manufacturers has never been more crucial. From telecommunications to healthcare, automotive, and robotics, PCBAs are the backbone of modern electronics.

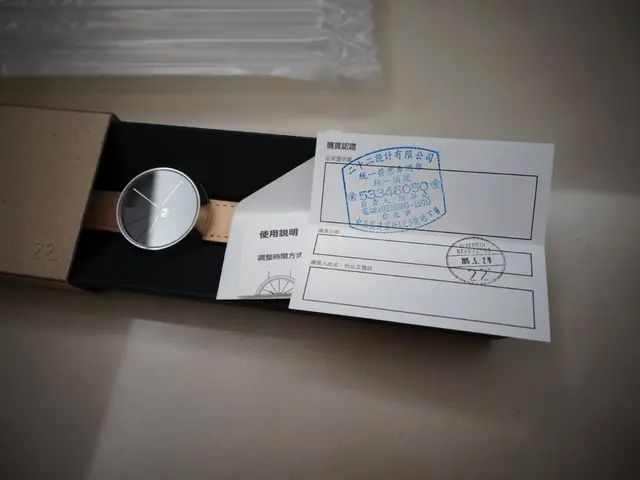

PCBAs combine the durability of rigid boards with the flexibility of flex circuits, making them ideal for compact or foldable electronics like cameras, medical devices, and wearables. Advanced PCBA manufacturers can guide in selecting the right materials and design specifications for Rigid-Flex PCBs, ensuring they meet the specific needs of these devices.

On the other hand, High-Frequency PCBs are essential in telecommunications, radar systems, and wireless communication devices. These boards require special materials like PTFE (Teflon) and precise impedance control. In the automotive industry, multilayer PCBs and advanced assemblies are being adopted for safety and performance, including Advanced Driver Assistance Systems (ADAS) and electric vehicle battery management.

When choosing a PCBA manufacturer, it's important to consider factors such as experience and technical capabilities, quality certifications, customization and flexibility, cost vs. value, communication and support. Don't cut corners when choosing a PCBA partner—choose one who can grow with your technology.

A reliable, technically capable PCBA manufacturer is crucial as electronics become more compact, complex, and connected. Whether for a few prototype boards or mass production of a multi-layer, high-frequency design, a quality PCBA involves precision, testing, and compliance with international standards.

Before committing to a PCBA manufacturer, ask questions about turnaround times, ability to handle specific materials and technologies, quality assurance measures, Design for Manufacturability (DFM) review, component sourcing, scalability, and industry specialization.

Modern PCBA manufacturers offer end-to-end services, including PCB fabrication, component procurement, Surface Mount Technology (SMT) and Through-Hole Assembly, functional testing and quality control, and turnkey and partial assembly options.

Companies like globalwellpcba.com offer advanced PCB solutions, expert assembly services, and a global outlook that meets the evolving needs of modern industries. Globalwellpcba.com, a company specializing in PCB (printed circuit board) manufacturing and assembly, has established an outstanding position in the industry due to high-quality production, advanced technology, and reliable customer service.

In conclusion, the right PCBA manufacturer ensures high-quality component sourcing, precision assembly, testing and quality assurance, on-time delivery, and long-term reliability. As technology continues to advance, the importance of choosing the right PCBA manufacturer will only grow.

Read also:

- visionary women of WearCheck spearheading technological advancements and catalyzing transformations

- A continuous command instructing an entity to halts all actions, repeated numerous times.

- Oxidative Stress in Sperm Abnormalities: Impact of Reactive Oxygen Species (ROS) on Sperm Harm

- Is it possible to receive the hepatitis B vaccine more than once?