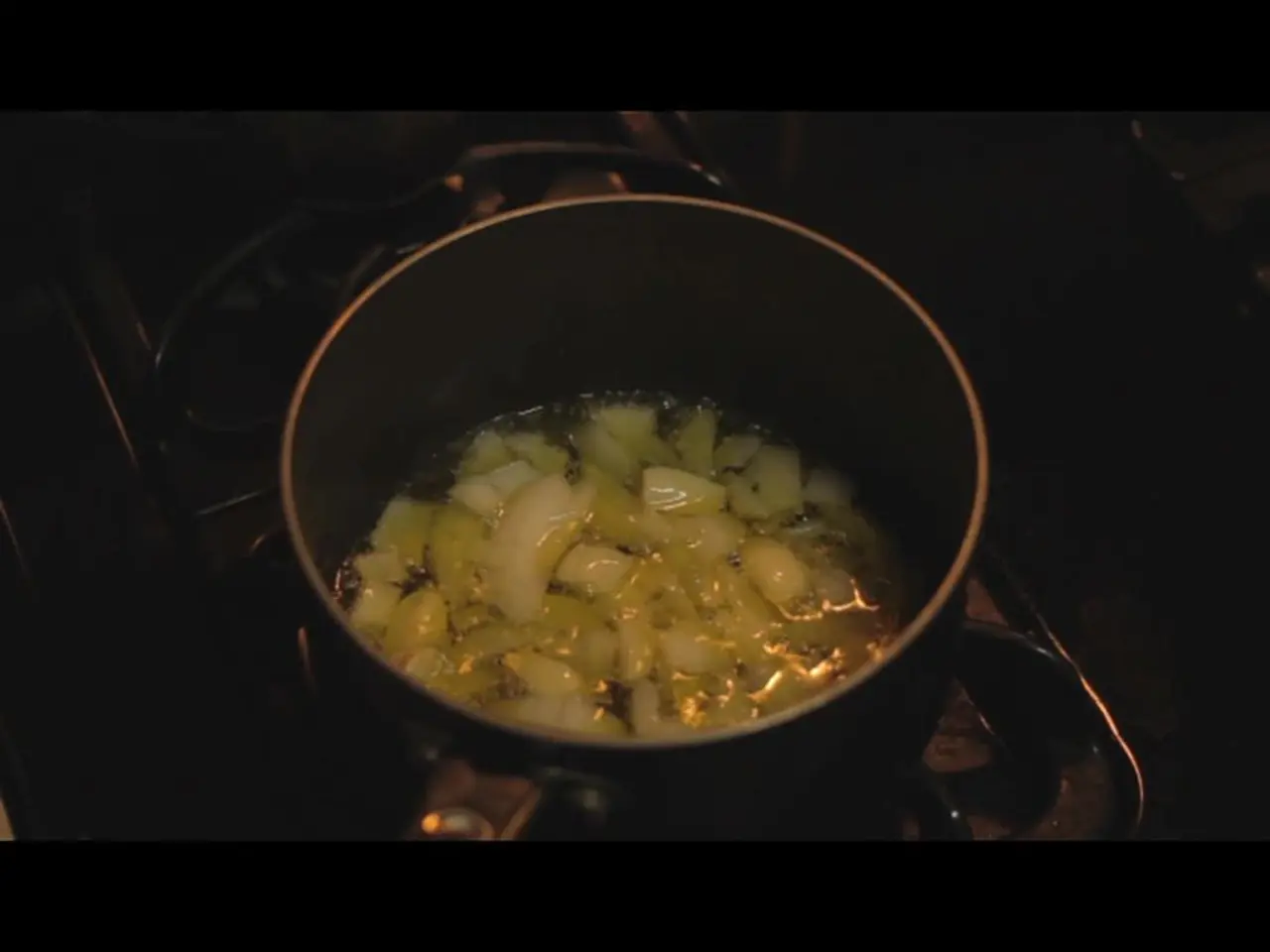

Single-use plastics are converted into oils using a nickel catalyst at minimal temperature, without the need for sorting process.

In a groundbreaking development, researchers at the University of Adelaide and Northwestern University have engineered a new nickel-based catalyst that could revolutionise the way we recycle single-use plastics. This breakthrough, published in Nature Chemistry, offers a promising path toward curbing the mountain of single-use plastic waste, turning a global environmental headache into a valuable resource stream.

The new catalyst, developed by Northwestern University chemists, can convert single-use plastics into fuels, waxes, and lubricants. It skips the time-consuming step of sorting plastics and is more efficient than current recycling methods, which are costly, energy-intensive, and often yield low-quality materials.

The precision design of the catalyst acts like a molecular scalpel, selectively targeting bonds in branched polyolefins while leaving others intact. This makes the process more efficient and less prone to the production of harmful by-products.

One of the most surprising outcomes came when the catalyst encountered polyvinyl chloride (PVC), a toxic polymer notorious for making recycling impossible. However, in this case, PVC improved the performance of the catalyst. Even when PVC made up a quarter of the waste mix, the catalyst kept working with better results, which could allow recyclers to tackle previously "unrecyclable" plastic streams.

The single-site nickel catalyst engineered by Northwestern University chemists operates at a temperature 100 degrees lower and at half the hydrogen gas pressure compared to other nickel-based catalysts. Moreover, it uses 10 times less catalyst loading and has an activity 10 times greater than other nickel-based catalysts.

Senior author Tobin Marks believes the breakthrough could transform recycling economics, making recycling more efficient, practical, and economically viable than current strategies. This could potentially increase the worldwide recycling rate of polyolefins, which currently stands below 10%.

Marine ecologist Nina Wootton from the University of Adelaide and her team are involved in developing this new catalyst. They aim to contribute to global recycling efforts and address one of the world's toughest environmental challenges: plastic recycling.

Neetika Walter, with over a decade-long career in journalism, wrote this article. She has worked with The Economic Times, ANI, and Hindustan Times, covering politics, business, technology, and the clean energy sector. This development promises to simplify plastic recycling and pave the way for a cleaner, more efficient chemical breakdown of mixed plastics, producing high-value oils and waxes that can be upcycled instead of downcycled.

The research was supported by the U.S. Department of Energy and Dow Chemical Company. This collaboration underscores the urgent need for innovative solutions to tackle the global plastic waste problem and highlights the potential for industry-academia partnerships in driving sustainable change.

Read also:

- visionary women of WearCheck spearheading technological advancements and catalyzing transformations

- Recognition of Exceptional Patient Care: Top Staff Honored by Medical Center Board

- A continuous command instructing an entity to halts all actions, repeated numerous times.

- Oxidative Stress in Sperm Abnormalities: Impact of Reactive Oxygen Species (ROS) on Sperm Harm